Forming Shoulder

Forming Shoulders

For our forming shoulders we only use stainless steel type 1.4301 or, upon request, type 1.4571. The collar sheet is pattern rolled and polished, the collar is brazed with silver solder.

We produce:

- Round forming shoulders

- Rectangular forming shoulders

- Stickpack forming shoulders

- Quad Seal Bag forming shoulders

Available seam types:

- Central seam

- Offset seam

- Overlap seam

- Flange seam

- Fin seam

- Straight seam

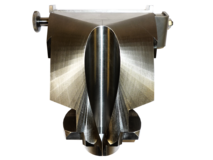

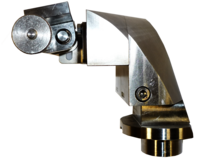

Forming Set

Forming Shoulders

We manufacture complete forming sets for all common machine types. A forming set consists of filling pipe plate, forming shoulder plate, stay bolt, filling pipe and forming shoulder.

For the plates and stay bolts we use anodized aluminium. If requested, all parts can alternatively be made of stainless steel (type 1.4301).